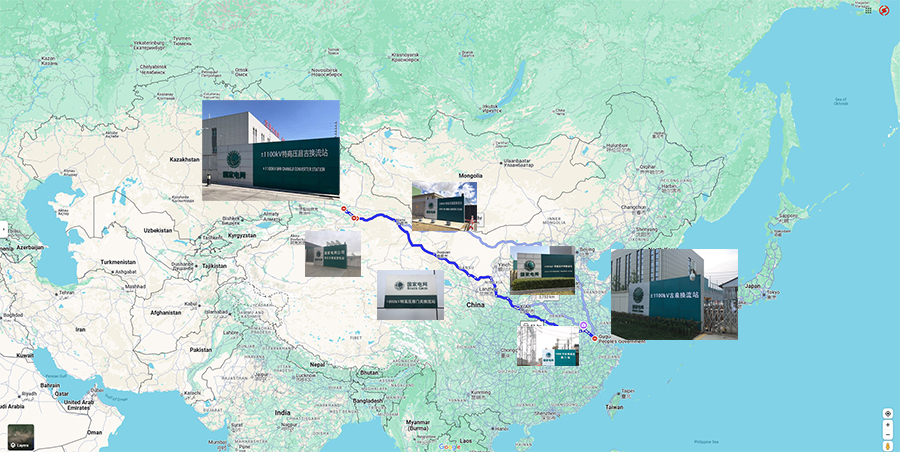

The ±1100 kV UHVDC power transmission line project from Changji to Guquan was approved by the National Development and Reform Commission on December 28, 2015. It starts from the Changji (in Xinjiang) converter station and ends at the Guquan (in Anhui) converter station, passing through six provinces and regions, including Xinjiang, Gansu, Ningxia, Shaanxi, Henan, and Anhui, with a total line length of about 3304.7 kilometers. The transmission capacity is 12 million kilowatts, and the voltage is ±1100 kV.

As of the end of 2024, SH POWER has participated in the construction of the world’s highest voltage level ±1100 kV Changji-Guquan UHVDC power transmission project, 22 1000 kV UHVAC power transmission and transformation projects, and 23 ±800 kV UHVDC power transmission and transformation projects.

The characteristics of UHV power transmission technology include high voltage levels, long-distance power transmission, the ability to achieve power transmission over 3000 kilometers and above, suitability for cross-regional and cross-border power transmission, large-capacity power transmission, high technical requirements, good economic benefits, minimal environmental impact, and a wide range of application scenarios.

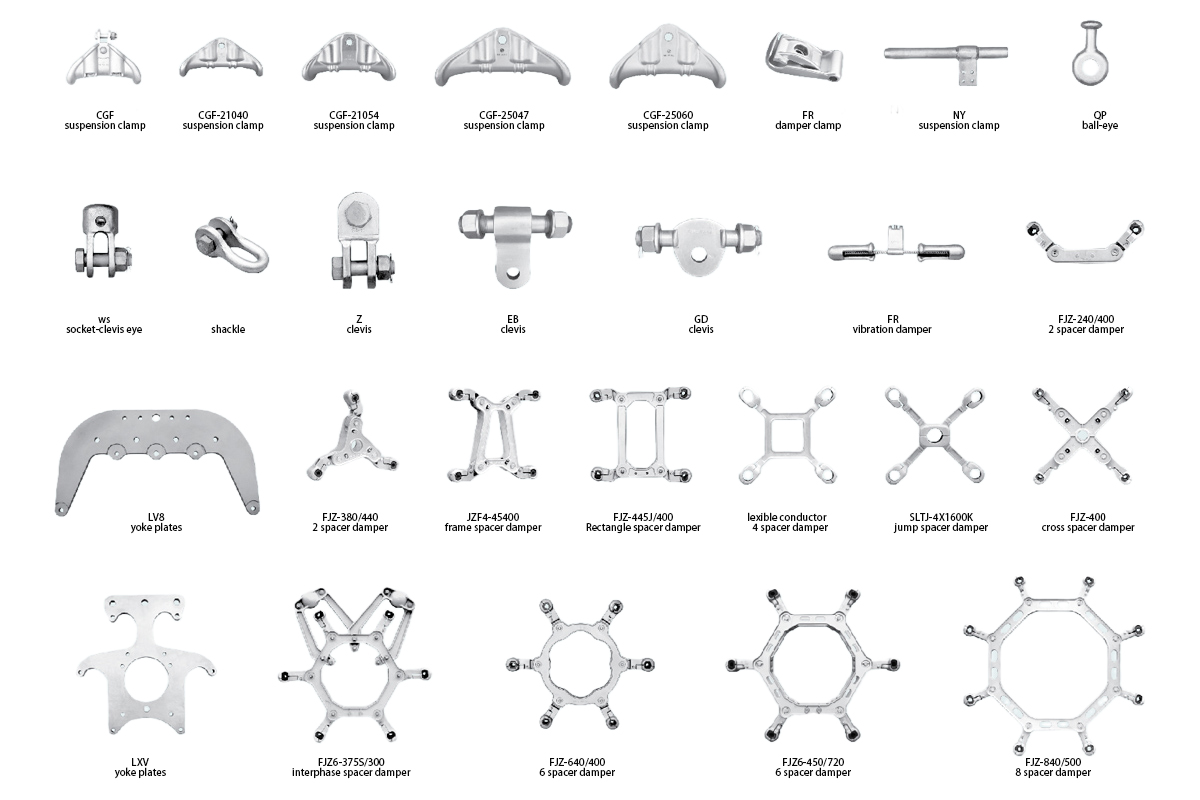

UHV hardware has unique requirements in design and manufacturing to ensure safe operation in high-voltage and high-current environments. The main features include high strength, high insulation, high-temperature resistance, fatigue resistance, precise design, a wide variety of types, long service life, and environmental friendliness, all of which ensure the safe and stable operation of UHV AC and DC lines.

The hardware provided by SH POWER in this project:

Product Introduction:

|  |  |  |

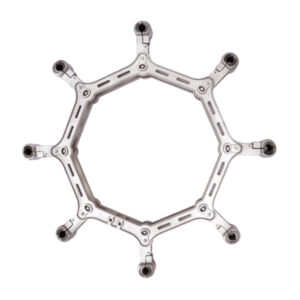

8 spacer damper(Casting) Suitable for voltage levels of ±1100 kV, conductor cross-sectional area of 1250 mm², splitting spacing of 550 mm, conductor splitting circle diameter of 1437 mm, and short-circuit current not less than 50 kA. | 8 spacer damper(Forging) Suitable for voltage levels of 1000 kV, conductor cross-sectional area of 630 mm², splitting spacing of 400 mm, conductor splitting circle diameter of 1045 mm, and short-circuit current not less than 50 kA. | 6 spacer damper(Forging) Suitable for voltage levels of ±800 kV, conductor cross-sectional area of 1250 mm², splitting spacing of 500 mm, conductor splitting circle diameter of 1000 mm, and short-circuit current not less than 75 kA. | suspension clamp Aluminum alloy forging process, suitable for a maximum conductor diameter of 70 mm, with a clamp grip strength of no less than 25% of the conductor’s rated breaking force, and a maximum clamp strength of 300 kN. |

|  |  |  |

NY suspension clamp Suitable for conductor JL/G2A-1250/100, with a tension clamp grip strength of no less than 313.36 kN. | vibration damper Suitable for a maximum conductor diameter of 48 mm. | ball-eye Nominal breaking load max 550 kN. | socket-clevis Nominal breaking load max 550 kN. |

|  |

| |

shackle Nominal breaking load max 1280kN. | z clevis Nominal breaking load max 2560kN. |