General requirements

1、Standardized and modular design.

- Flexible stackable deployment to meet different solar power generation requirements in various capacities and locations.

- Compact structure, integrated configuration, plug-and-play design for rapid implementation of smart zero-carbon upgrades in industrial parks.

2、High reliability and high safety.

- The brand of medium and low-voltage cabinets and prefabricated enclosure is consistent, ensuring integrated integration.

- Meets the requirements for use in harsh environments, with the enclosure being corrosion-resistant and thermally insulated. It is sturdy and reliable, and the steel structure can meet the requirements for C5-VH high salt-mist environmental use.

- Can be equipped with fire alarms and video surveillance systems to ensure a high level of security in the operating environment.

3、Comfortable and safe walk-in prefabricated substations.

- Reserved space suitable for equipment operation and office space for personnel.

- The substation is insulated and fireproof, using rock wool boards with a thickness of no less than 50mm, which are A1-grade non-combustible. The floor thickness is no less than 6mm.

- Indoor temperature is maintained between 0-35°C to ensure stable equipment operation and a comfortable working environment for personnel.

Case 1 : 2-12MW New Energy Distribution Module Solution

| Photovoltaic Power Generation+Wind farm ≤4MW | 4MW≤ Photovoltaic Power Generation+Wind farm ≤6MW | 6MW≤ Photovoltaic Power Generation+Wind farm ≤12MW |

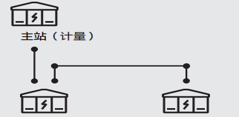

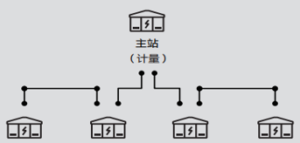

| Single Station Solution | Combination scheme one | Combination scheme two |

|  |  |

Distributed photovoltaic installation has a compact coverage area, making cable installation convenient and cost-effective. The site is limited, not suitable for new construction or expanding distribution stations. Suitable for a walk-in working environment. | Distributed photovoltaic installations have a wide coverage area, and sometimes cables need to be laid over long distances, leading to potential construction difficulties. The main station is well-suited for walk-in work environments.

| Flexible stacking deployment of main and sub-stations according to photovoltaic installation needs. Distributed photovoltaic installations cover a wide range, or cable laying is too long. Main station is suitable for walk-in work environments. |

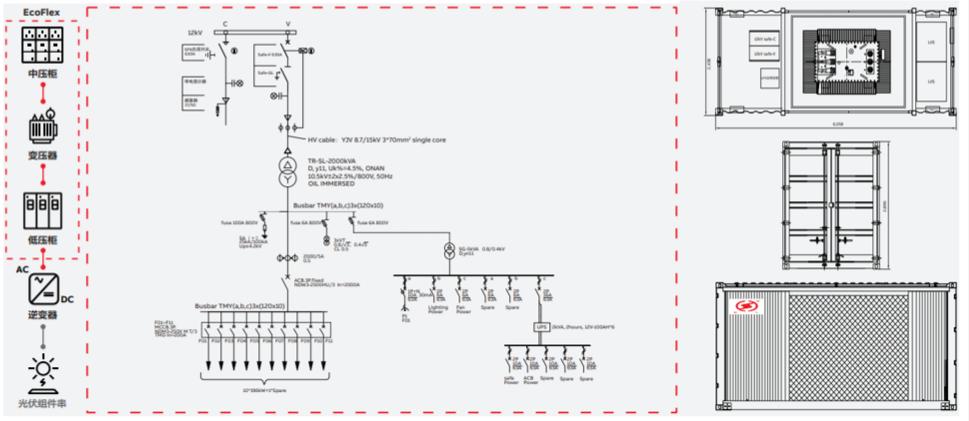

Case 2 : 2-4 MW New Energy Distribution Single Station Solution: eHouse Prefabricated Substation

| System Architecture Diagram |  |

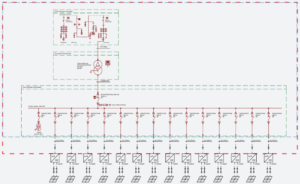

| Single-Line Diagram of the System | (Photovoltaic Installed Capacity:2~4MW) |

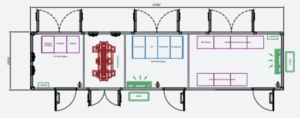

| Site Plan/Layout Diagram |  |

| Equipment Configuration | Prefabricated Substation : 2.8m*12.192m*2.896m HV Switchgear : 12kV,KYN/SNZX Transformer : ≤4000 kVA,10.5/0.54 (0.8) kV LV Switchgear : MNS |

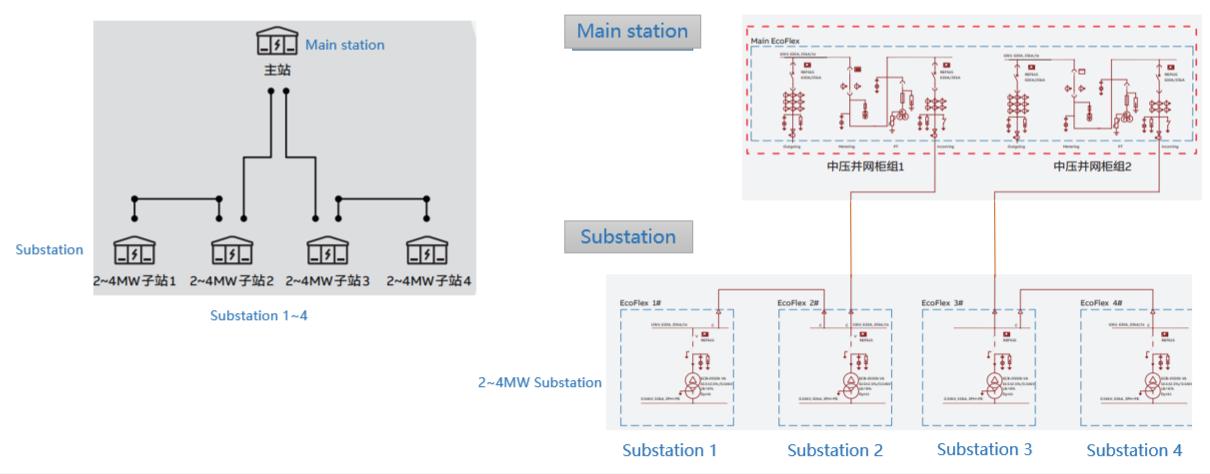

Case 3 : 4-12MW New Energy Distribution Combined Solution – Substation Module

Case 4 : 4~12MW Renewable Energy Distribution Modular Prefabricated Substation

Main Station + Substation Mode: Choose the configuration of the main and substation based on the actual power generation capacity of the project.