Advantage Analysis:

- The equipment has a small footprint and occupies minimal space, making it particularly suitable for areas with limited available land, especially in densely populated regions.

- After the equipment arrives at the site, the entire substation construction can be completed within a week, enabling rapid station deployment. The equipment manufacturing process takes 2-3 months, and on-site construction can be finished within a month to achieve power delivery, addressing the challenge of long construction periods for grid-connected main stations.

- High operational reliability, low maintenance workload, and extended overhaul intervals.

- Intelligent design with online monitoring capabilities, catering to diverse customer usage requirements.

- High degree of integration, fully modular design, catering to various wiring requirements.

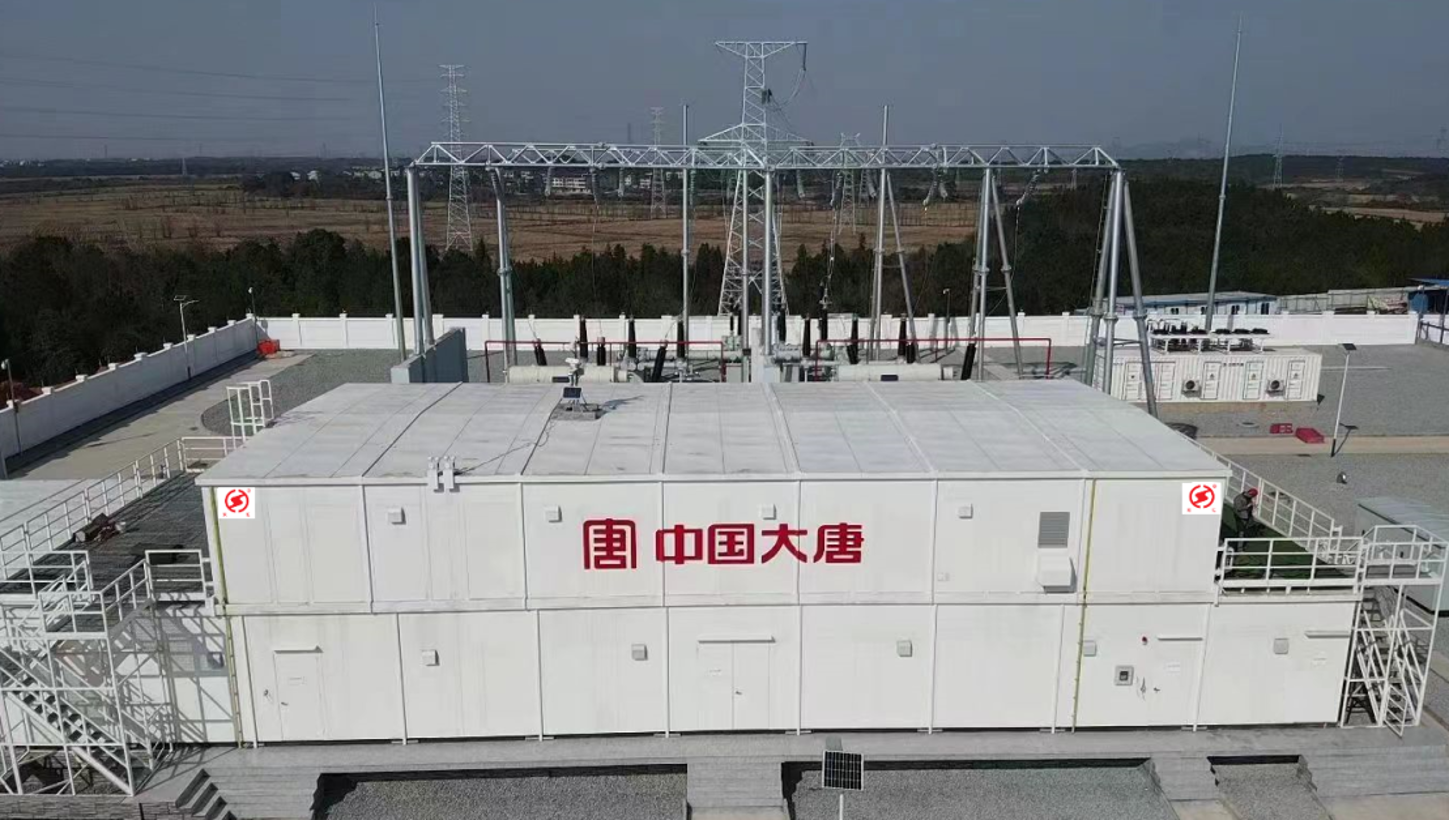

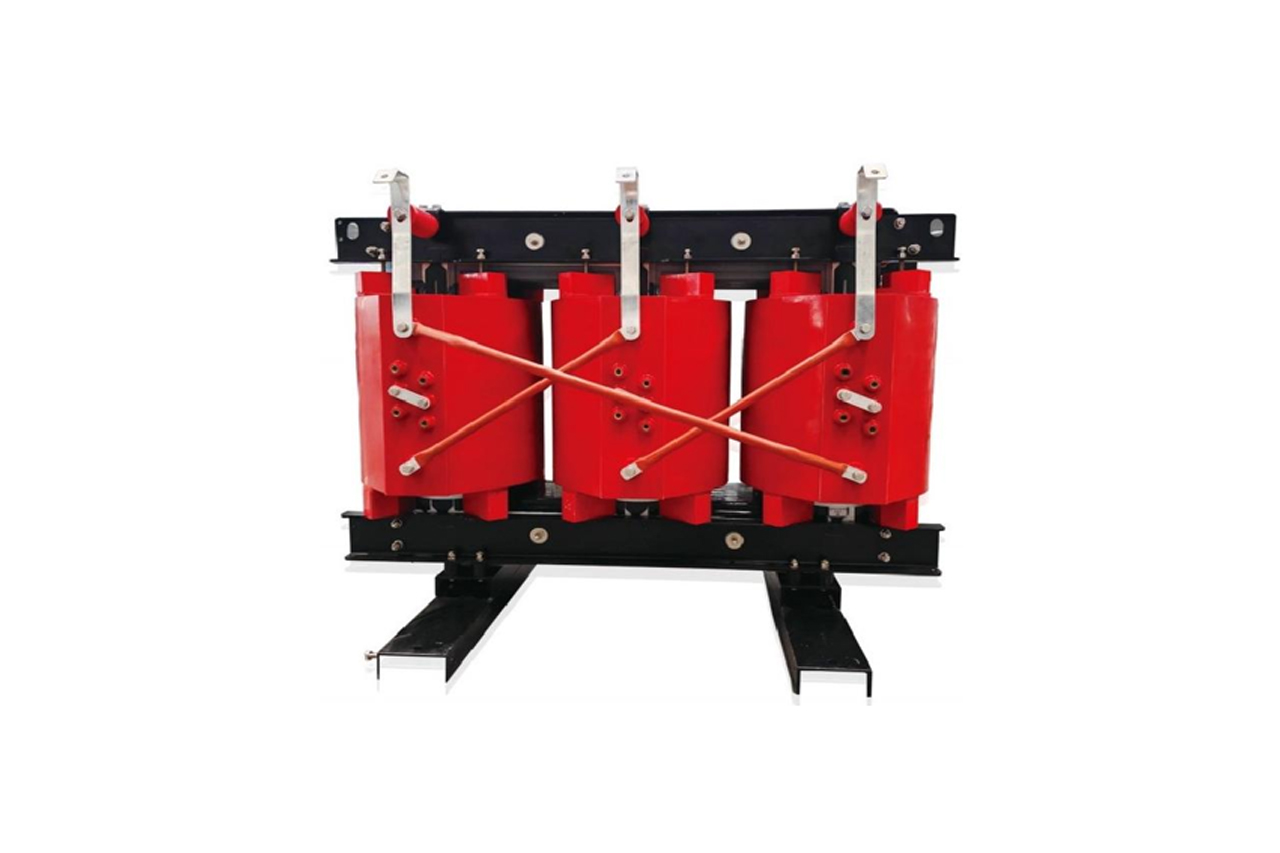

35kV modular prefabricated intelligent substation solution, adhering to the concept of full-factory prefabrication. All primary and secondary equipment, including 35kV switchgear, secondary self-protection devices, reactive power compensation devices, and main transformers (if needed), are placed inside double-layer, sealed, thermally insulated, and anticorrosive prefabricated enclosures. Currently, we have supplied projects in Wuhai and Wuda, Inner Mongolia, as well as integrated wind-solar power and hydrogen production demonstration projects (300MW each) in Zhangjiakou, which have all been commissioned.